The Inspiring Journey: The School Life of the Earth Leader

The Making of a Global Icon

The school life of the Earth Leader is not just a tale of academic pursuit but a blueprint for transformative leadership in the 21st century. Behind every great leader lies a foundation built on education, early influences, and life-defining experiences. In this extensive exploration, we delve deep into the school life of the Earth Leader—a figure symbolic of environmental stewardship, resilience, and unwavering commitment to planetary health. This article aims to shed light on how school life shaped this global changemaker, revealing the values, struggles, and victories that laid the groundwork for an unparalleled journey in ecological leadership.

The Early Years: Seeds of Consciousness

Long before being recognized as the Earth Leader, this young visionary exhibited a deep reverence for nature. The school life of the Earth Leader began in a modest institution surrounded by lush greenery and a community deeply connected to the land. From the first day, the Earth Leader was different—asking questions about the wastefulness of plastic lunchboxes, advocating for tree planting during recess, and initiating clean-up drives as early as primary school.

Teachers remember a student who was quiet yet fiercely driven, often reading books on ecosystems and animal conservation instead of fairy tales. The school library became a sanctuary, where the Earth Leader explored the writings of Rachel Carson, Jane Goodall, and local environmental activists. These formative years were not just about learning to read and write—they were about forming a vision for a greener tomorrow.

A Unique Approach to Learning

The school life of the Earth Leader was marked by a distinct approach to education. While most students chased grades, the Earth Leader sought understanding. Subjects like biology, geography, and environmental science became lifelines. Field trips were not leisure activities but learning opportunities—chances to observe biodiversity, analyze ecosystems, and converse with indigenous communities.

The Earth Leader wasn’t always the top of the class, but excellence came in a different form: empathy, critical thinking, and collaboration. Group projects often revolved around climate issues, water conservation techniques, and recycling programs. It was during these group sessions that leadership qualities began to shine. Rather than dominating, the Earth Leader empowered peers, distributed responsibilities fairly, and turned every project into a shared mission.

Challenges and Social Obstacles

Not every chapter in the school life of the Earth Leader was idyllic. Like any transformative figure, this journey was riddled with challenges. Skepticism from classmates, resistance from faculty who preferred traditional methods, and the emotional toll of confronting ecological apathy were daily hurdles.

The Earth Leader was often labeled as “too serious,” mocked for choosing community clean-ups over sports, or dismissed for warning about climate change in school assemblies. Yet, these experiences only strengthened their resolve. Skeptics turned into supporters, and the school became a miniature model of environmental responsibility.

Building Movements from Classrooms

By middle school, the Earth Leader had initiated the Green Student Union—a student-led organization focused on sustainability. Starting with ten members, it grew into a movement that influenced curriculum changes, initiated zero-waste policies in cafeterias, and hosted annual eco-fairs.

The school life of the Earth Leader became synonymous with innovation and advocacy. From building solar-powered science projects to persuading local government bodies for tree planting permissions, the classroom was no longer a limitation—it was a launchpad. Leadership was exercised through actions, not titles. Through inclusive strategies and grassroots energy, the Earth Leader made environmentalism accessible and exciting for students of all ages.

Educators Who Made a Difference

A handful of visionary educators saw potential beyond the conventional report card. These teachers provided platforms for expression, whether through student newspapers, debates, or environmental clubs.

One science teacher, in particular, played a pivotal role. Recognizing the Earth Leader’s deep interest in climate issues, they arranged guest lectures, facilitated access to university-level resources, and even nominated them for national environmental contests. These gestures, though small, created ripples that transformed self-belief into activism.

Environmental Projects that Left a Mark

The school life of the Earth Leader was filled with practical initiatives that had a lasting impact. Highlights include:

- Rainwater Harvesting Project: Designed and implemented by the Earth Leader, this project significantly reduced the school’s water dependence.

- Plastic-Free Campus: Through persistent campaigning, the Earth Leader helped eliminate single-use plastics from the school premises.

- Community Tree Drive: Coordinated with local farmers and students to plant over 2,000 native trees in surrounding neighborhoods.

These projects weren’t merely symbolic. They created quantifiable change, altered school policies, and instilled environmental awareness in hundreds of students.

Transforming Adversity into Advocacy

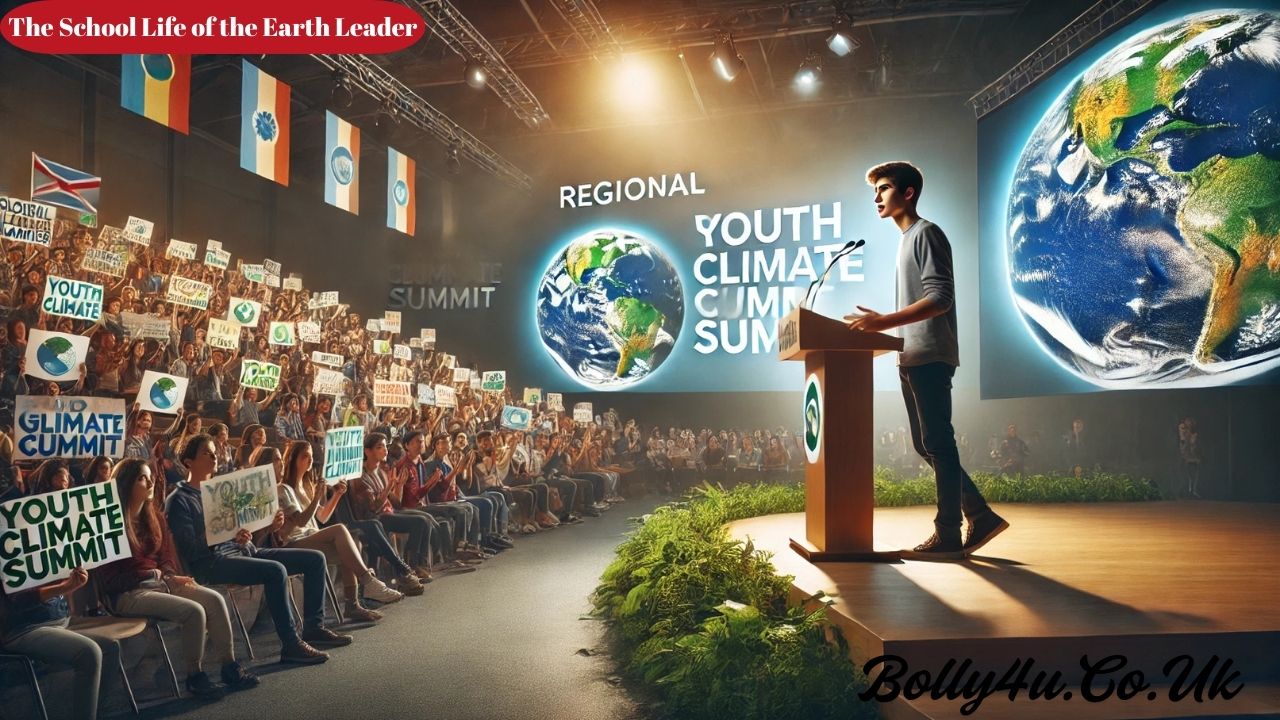

Bullying, burnout, and bouts of self-doubt were part of the school life of the Earth Leader. However, these trials were converted into fuel for advocacy. Public speaking, a former fear, became a strength. After being laughed offstage during an early presentation on global warming, the Earth Leader trained rigorously, eventually becoming a voice for youth climate action at regional forums.

Mental health also became an area of focus. Understanding that eco-anxiety affected many students, the Earth Leader collaborated with counselors to introduce peer-support systems. This holistic approach to leadership made them relatable, not just revered.

Preparing for a Global Mission

High school marked the transition from local hero to global visionary. The Earth Leader’s academic performance, though consistently solid, was now bolstered by a resume full of impactful work. Scholarships, internships with environmental NGOs, and recognition from international platforms followed. Yet, humility remained a defining trait.

Unlike many high achievers, the Earth Leader never detached from their roots. They frequently returned to their school, mentoring younger students, sharing experiences, and reinforcing the message that leadership starts in the classroom.

Legacy and Influence

The school life of the Earth Leader has become a case study in education systems around the world. What began as one student’s mission evolved into a global campaign, with ripples reaching schools in remote villages and urban metropolises alike.

Conclusion: A Blueprint for Tomorrow

The school life of the Earth Leader is more than an inspiring tale; it is a roadmap for the future. It proves that leadership is not born in political chambers or corporate boardrooms but in school corridors, science labs, and student clubs. It affirms that the environmental crisis can be addressed if our schools become centers of consciousness and courage.

Also Read: Discudemy: The Ultimate Platform for Accessing Free Learning Resources and Courses